- Overview

- Warranty

- Product Videos

- Custom Field #1

- Custom Field #2

- Reviews

- Assembly & Setup

- Contact Us

- Shipping

- Wholesale

Product Description

The Atlas WB 49 computer wheel balancer incorporates all the great features (AND MORE) of the Atlas WB41 computer wheel balancer.

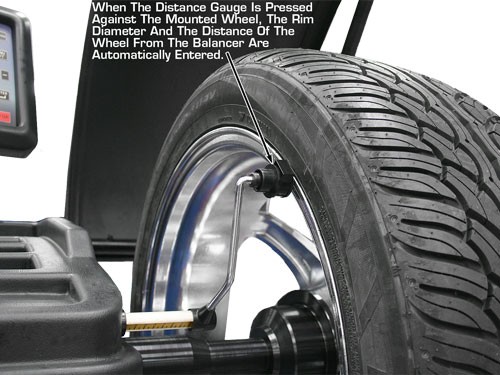

All truck and car computer wheel balancers require the input of three different measurements; rim width, rim diameter, and distance of mounted wheel assembly from the computer wheel balancer. The Atlas WB41 requires the operator to manually enter these three parameters. The Atlas WB49 requires the operator to enter ONLY the wheel width data. The other two parameters are entered automatically when the distance gauge (located near the balancer's mounting shaft) is extended to contact the inside of the mounted wheel assembly.

The Atlas WB 49 is designed for those shops balancing 10-50 sets of passenger tires per day.

How a Wheel Balancer Works:

The computer within the balancer receives the premeasured values of wheel dimensions and responds to the output of a rotational speed sensor that monitors the rotational speed of the shaft. When the required speed is reached, the mechanical system automatically decouples the powered cranking shaft from the wheel shaft so that there can be no externally applied disturbances for the subsequent measurements of imbalance. Multiple spaced transducers along the shaft determine the wheel run-out attributable to imbalances in both the inner and outer wheel rim planes and the computer provides output signals indicative of the correct balance weight and the mounting positions of the weights on the wheel rim.

Benefits of the Atlas WB49 Wheel Balancer

"Split-Weight" Feature: The WB-49 has the automatic data entry feature not found on the Atlas WB-41 . The measuring guide rod for the automatic data entry is also used to determine the placement of wheel weights when used with the " split-weight " feature of the WB-49. The WB-41 does not have the split weight feature programmed into its software. Many custom rims have decorative spokes and certain customers do not want any wheel weights to be " seen " on these fancy wheels. The only place to " hide " the stick-on weights is behind the spokes of the wheel. The " split-weight " feature allows the operator to " split " the correct amount of weight and " hide " these weights behind the spokes. The measuring guide rod is used to pinpoint the placement of the weights and the WB-49's software determines the amount of weight that needs to be applied.

Self Calibrating: The Atlas WB-49 is a self-calibrating computer wheel balancer. There is no need to calibrate the balancer each morning when you turn it on.

Wheel Weight Positioning Modes: The Atlas WB-49 has several different wheel weight positioning modes that allow the operator to the spin the wheel assembly one time and identify several different weight positions with just a touch of the button. The Atlas WB-49 uses the most up to date (Atlas exclusive) software to ensure accurate out of balance measurements. Many custom wheel owners want their stick on wheel weights to be applied only to the inside of the rim, and the Atlas WB-49 shows the operator exactly how much weight is required and where to apply the weight on the inside of the rim with just one spin. Conventional steel wheels require a clip on weight to be attached to the outside and the inside of the rim. The Atlas WB-49 can automatically calculate where the weights need to be placed with just the touch of a button. 130 LB.

Wheel Assembly Capacity: The Atlas WB 49 wheel balancer balances wheels that weigh up to 130 LB. Many balancers claim that they have 150 lb wheel capacity. There is a BIG difference between the shaft being able to support a 150 lb wheel assembly and the balancer being able to accurately balance the 150 lb. wheel assembly.

Extra Large, Raised Display: The extra large raised LED display panel and increased wheel weight tray capacity make the Atlas WB-49 computer wheel balancer the perfect choice for the professional tire dealer.

Auxiliary Brake: The Atlas WB-49 has a foot pedal auxiliary brake that allows the operator to hold the wheel assembly in the correct position when attaching the wheel weight to the rim.

Newly Designed Computer Board: Finally, the Atlas WB 49 uses a newly designed computer board system that makes replacement of the computer board as easy as plug and play. Many of the Asian manufacturers are using computer technology that is over ten years old. All of the Atlas balancers are implementing the newest and most reliable computer technology available. This improved technology is one of the many reasons that Atlas balancers will provide years of reliable service.

Ease Of Use And Repair: The Atlas WB-49 is very a simple, yet sophisticated wheel balancer. Each electrical component part is virtually " plug and play " so repair is easy when it is time to replace parts. The Atlas WB-49 is capable of self-diagnosing problems and displays error codes so the operator can make the necessary adjustments or repairs in his own shop. There is no need to wait for the high priced service technician to visit your store. The simplicity of the Atlas WB-49, both in ease of use and ease of repair, make this balancer the perfect choice for your professional tire shop.

Quality: Most computer wheel balancers are not made in North America. Most Big Name wheel balancer companies have one or several models of their computer wheel balancers line made in China. Famous brand names such as Hunter ® wheel balancers, Corghi ® wheel balancers, Accu-Turn ® wheel balancers, Snap-On ® wheel balancers, Hofmann Wheel balancers ®, Ranger ® wheel balancers, and many other computer balancers manufacturers do business either directly or indirectly with Chinese manufacturers. Many people believe that only the top quality computer wheel balancers and tire changers are manufactured in Italy. Many so-called Italian tire changers and Italian computer wheel balancers are SHIPPED to North America from Italy...but are actually made in China. We do business directly with many of the same Chinese factories that private label for the Italian " manufacturers " . Atlas Automotive Equipment of CANADA sells the same quality equipment, but at a huge price difference. We are proud to provide similar equipment as some of the Big Name Brands but without the Big Name Price. We know where our equipment is made and have visited the factories and suppliers in China. Most sales people of the Big Name Brand distributors have no idea where there equipment is made. These sales people have never been to any factory that makes computer wheel balancers or tire changers. They only know to tell the potential customer to not buy any tire changer or wheel balancer that comes from China. Little do they know!

| Highlights

| |

| Specifications | |

| Max Tire Diameter | 39" |

| Rim Sizes (cars and light trucks) | 10"-32" * |

| Rim Width | 1 ½"-20" |

| Shaft Size | 40mm Max. |

| Max. Wheel Weight | 150 LBS. |

| Balancing Speed | 150 R.P.M |

| Automatic Data Entry | YES |

| Truck Adapter Set | Optional |

| Shipping Weight | 380 LBS. |

| Power Supply | 110V 1Ph |

| Motor | ¼ HP |

| Warranty | 1 year limited |

| Display | Standard or Metric |

| Accuracy | 1 g |

| Weight Position Resolution | 1.4 Degrees |

| Self Calibration | Yes |

| * Requires manual input of some data from 23"-32". | |

Warranty

NOTE: ALL WARRANTY CLAIMS MUST BE PRE-APPROVED BY THE MANUFACTURER TO BE VALID. Complete Warranty and Legal Terms Atlas Automotive Equipment of CANADA offers a one year limited structural parts warranty on all Atlas wheel balancers. Atlas Automotive Equipment of CANADA warrants the equipment to the original purchaser against defects in material or workmanship under normal use for a period of one year from the date of purchase. This limited warranty shall be limited to the repair or replacement of materials or parts found defective, at the discretion of Atlas Automotive Equipment of CANADA. Electrical component parts carry a 90 day warranty, motors carry a one year warranty. Our limited warranty policy (one year parts only) does not include a labor warranty. Our products are sold at such a competitive price that Atlas Automotive Equipment of CANADA cannot afford to send technicians into the field to repair the Atlas wheel balancers. We assume that the buyer of our wheel balancer is mechanically inclined or has employees that are mechanically inclined.Our wheel balancers are built with “plug and play†parts that make repairs very easy. This is the same philosophy that the Personal Computer Industry has used for many years.Our wheel balancers include a self-calibration feature that makes daily calibration obsolete. We offer a toll free number 1-800-400-5438 for service and parts information. This toll free number is directed to our Calgary, AB location. The service and parts department is open from 8 am to 5 pm MST from Monday to Friday.There are certain parts that are considered “wear items†as well as cosmetic defects or blemishes that do not interfere with functionality of the wheel balancer are NOT included in the one year warranty. Parts that have been subjected to abuse will NOT be considered for warranty. REPEAT: IF YOU ABUSE YOUR WHEEL BALANCER (LIKE PLUG A 110 VOLT CORD INTO A 220 VOLT OUTLET, USE YOUR WEIGHT HAMMER INSTEAD OF YOUR FINGERS TO ENTER PARAMETERS INTO THE KEYPAD, OR DRIVE YOUR CAR INTO THE SIDE OF THE BALANCER AND BEND THE SHAFT) THEN THE WARRANTY ON YOUR BALANCER IS VOID.Product Videos

Videos Hide Videos Show Videos

-

How to Calibrate The Atlas WB49 Wheel Balancer

A walk through on how to calibrate your Atlas WB49 computer wh...

-

The Atlas MC And MCXLT Balancer Motorcycle Kits Make It Easy To Balance Motorcycle Wheels

-

Atlas Universal Adapter For Wheel Balancers

Atlas Universal Adapter (UA) is designed for wheels that have ...

-

Atlas MC-XLT Kit

The Atlas MC-XLT adapter kit will allow your Atlas (passenger ...

-

Atlas MC Kit

The Atlas MC adapter kit will allow your Atlas (passenger and ...

-

Atlas Spoke Support Adapter (SSA)

Greg Smith Equipment offers the Atlas spoke support adapter (S...

Product Reviews

Product Assembly & Setup

Selling automotive equipment we have found that most of our customers are mechanically minded and look forward to settting up and assembling their new purchase. Most items we offer can be setup and assembled by two people within a reasonable time frame. Before tackling this project here are a few tips that we think will make your life a little bit easier:

- Review the manually fully before you begin setup. The manual should be included with your item but if you cannot locate it simply go to the product page on our website and download it for FREE. This manual has been put together and maintained over the years and will include all the tricks we have learned to make the assembly of your as seamless as possible

- Don't like reading or don't need the manual? That's fine, but maybe take a minute and check out the videos we have posted on each of the product pages. We understand that some people have the ability to problem solve on their own but why not get the inside information so you can spend less time having to problem solve?

- If you haven't already received your item, get an uderstanding of you will need to transport or unload it. Shop equipment like tire changers and wheel balancers are a dream to handle compared to car lifts. If you are assembling your car lift take time to plan our your install.

- Start by making sure the install location and area(s) surrounding it are clean and clear making it easy for you to move around and manipulate the pieces.

- Try to get the entire crate close to the install area without impeding it. There are some heavy pieces that need to be moved into place and the less you have to move them the better.

- Disassemble the packaging and pieces and have a look through them to ensure all pieces are there and get an idea of what each item is. You are going to need them at one point and if you have someone holding a heavy item while you search out a bolt or hose it is going to be a long day!

- If you are reading the manual, read 2-3 steps ahead of where you are at. We have heard time and time again how a customer has installed their lift to 90% only to find that a hose or cable needed to be put in place two steps earlier and now they have to essentially disassemble the lift only to put a small piece in place and then reassemble it.

- Be sure to review the electrical requirements of the product your are purchasing. Some items are supplied in either 110V or 220V. Others are manufactured so you can just plug it in while some have a "pig tail" which means you will need an electrician to either hard wire it to your panel or install a plug

- If you are assembling a car lift, you will need hydraulic fluid to make the lift work. PLEASE NOTE: we do not supply the hydraulic fluid for your lift. In general we recommend AW-32 hyraulic fluid for use in all of our car lifts (regardless of the type). A 5 gallon pale is typically more than enough and will usually leave you with a little extra

- When filling your hydraulic fluid for the first time don't rush the process. Fill the resevior to 1/3 or 1/2 and then run the lift up and down. Get the air and kinks out and then, when the lift is in the lowest position, fill it to 2/3 or 3/4 and run the lift up and down again. DO NOT fill the resevoir past 1/3 or 1/2 when the lift is in the raised position as there is flud throughout the cyclinders and other components. We have heard many times that a customer has filled the resevoir full when the lift is in the raised position and the as soon as they begin lowering the lift the resevoir becomes overfilled and spills all over the shop. This is a huge mess to clean up.

- Some hydraulic cylinders may be "air locked" from manufacturing which will not allow the piston to extend when pulled by hand. This does not mean the cyclinder is damaged, it is simply a result of the manufacturing process. To overcome this, start by ensuring that your feeder hoses to the cylinder are not connected (this would close the system and will not let air in or out). Using a ratchet strap or similar item, slowly put tension on the piston end and gently apply pressure trying to extend the piston out of the cylinder. Resistance will build up in the first couple inches of extending and then the "air lock" should break. You might get a little pop and the ratchet strap will loosen suddenly (hence the reason to apply pressure slowly) and now you should be able to extend and retract the piston by hand with little effort.

These tips are friendly suggestions from us and the years of experience we have gained working with these products. Although they don't apply to every product, every time we hope that you will take them at face value while still reviewing the other information (such as manuals and videos) we provide in regards to assembling and setting up your product. Your safety and satisfaction are our paramount concerns. If there are any questions or concerns throughout the assembly or operation process of your product please do not hesitate to contact us.

Contact Us

For all customer, vendor and media inquiries we encourage you to contact us VIA your preferred method:

By Phone:

Local 403.398.5020

Toll-Free 866.284.8604

Monday-Friday

8:00am-5:00pm MST

By Fax:

Toll-Free 866.398.5020

By Email:

customercare@atlasautoequipment.ca

In Person

Click here to view our locations.

8:00am - 5:00pm MST

Weekends & Holidays

Closed

NOTICE REGARDING OUR SHOWROOM

In an effort to offer our customers the highest quality products at the most competitive prices our business structure does not allow us to operate a showroom. Removing this expense is one of the many tactics we employ to ensure our customers continue to get the most cutting edge deals.

If you need clarity on specifications, product styles or if you would like more information than what we offer on our site be sure to contact us and one of our friendly customer service staff will be happy to assist you.

Shipping Information

Knowing that each customer will have unique needs when receiving their product, we strive to offer shipping solutions for every customer regardless of their location.

Please contact our friendly customer service staff toll free at 1-866-284-8604 and they will be happy to assist you in finding the most convenient and cost effective options for you to receive your order.

Both shipping and pickup options are available.

Wholesale

Are you interested in reselling these items or making a wholesale purchase? For qualified individuals a wholesale program is available upon request. We have reasonable quantity requirements and will be happy to listen to your specific situation to allow us to build a program that is mutually beneficial. Please contact us VIA telephone 1-866-284-8604 or email customercare@atlasautoequipment.ca to submit your request.

Financing

We are happy to be able to offer a financing option as a new method of payment for your purchase.

Available through a Canadian based third party company, financing can be beneficial for many reasons:

- You don't have to pay for the total price upfront

- Depending on information provided there are reasonable or even zero"down payments"

- Amortizing the purchase over a specified period allows you to make budgeted payments

- Having budgeted payments allows you to recover the cost of the machine through revenue over an extended period

- Reasonable interest rates

- Various security options

Whether you just want to make smaller payments or prefer the financing method our third party finance company will work quickly to provide you with all options available.

Their friendly approach ensures that all customers looking to finance or just exploring the possibility will receive accurate information with no hidden fees, terms or tricks.

If you would like more information on financing please contact our Customer Care Team toll free at 866.284.8604 or VIA email customercare@atlasautoequipment.ca.

We also welcome you to contact our leasing partner directly to begin the pre-approval process or to address any of your questions.

Click on the link below and you have access to a payment calculator and the ability to apply for financing online.