- Overview

- Warranty

- Product Videos

- Custom Field #1

- Custom Field #2

- Reviews

- Assembly & Setup

- Contact Us

- Shipping

- Extended Warranty

- Parts

Product Description

"This item is currently out of stock in Ontario at this time"

A4_412A_Manual_ATTD-412A(needsnewfile).indd (gregsmithequipment.com)

4postbleeding.indd (gregsmithequipment.com)

The Atlas 412A 12,000 pound capacity four post alignment lift is designed and built to commercial grade standards and will provide many years of service. Our Atlas lifts offer many exclusive features not found on many other competitor’s lifts.

The Atlas 412A incorporates many structural and cosmetic features that are found on lifts costing thousands of dollars more money. The 412A is tested to ensure that this lift system will perform flawlessly at its rated capacity.

The Atlas 412A uses a high strength cable system (with a under runway oversized hydraulic cylinder) powered by a 220 volt (single phase) power unit to raise and lower the lift. Many competitors use an “old style” chain lifting system with an exposed hydraulic cylinder system. Old style chain lifts are difficult to “level” properly and the exposed hydraulic cylinder is responsible for numerous “door dings”.

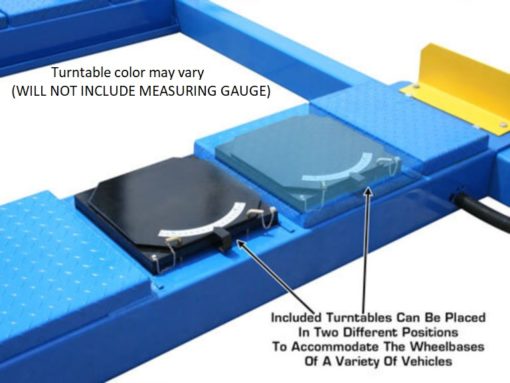

Besides having all the heavy duty features of the Atlas 412, such as “tracks” between the runways to allow the use of a rolling bridge jack (the Atlas® RJ6BK) on the lift (rolling jacks sold separately) the 412A features slip plates and alignment turntables. The slip plates are built in and are assured to be level with the turntables. The turntables can be set in different positions on the runway to accommodate a wide variety of wheelbases. The 412A also features metal cover plates to replace the turntables when not in use and so the lift can be used for more than just alignments.

Features:

- 12,000 lb. Capacity

- Heavy Duty, Commercial Grade

- Extra Tall, Extra Wide & Extra Long

- Built-In Slip Plates & Alignment Turntables Included

- Multiple Positions for Turntable Placement

- Runway Covers Included (when Turntables are Removed)

- Air Operated Single Point Lock Release (External Air Supply Required)

- Lock Ladder Design

- Double Lock Safety System

- Powder Coat Finish

- Steel Approach Ramps Included

- Additional Drive off Ramps Available (Sold Separately)

- Runway Extensions Available (Sold Separately)

- Mounting Hardware Included

- 220volt/1phase Electric Operation (Requires a 30amp Breaker)

- Shipping Weight: 2,900 lbs.

Specifications:

| Atlas ATTD-412A Specifications | ||

| Capacity | 12,000 lb. | |

| Lifting Height | 77 3/4" (6' 5 3/4") | |

| Overall Width Of Columns (Without Motor) | 126 1/4" (10' 6 1/4") | |

| Overall Width Of Columns (With Motor) | 135 1/4" (11' 3 1/4") | |

| Overall Length With Approach Ramp | 236 1/2" (19' 8 1/2") | |

| Length Between Columns | 183 1/4" (15' 3 1/4") | |

| Runway Length | 194 1/2" (16' 2 1/2") | |

| Runway Width | 20" | |

| Thickness Of Runway | 7 1/2" | |

| Width Between Runways | 43 1/4" (w/ Rail 39 3/4") | |

| Outside Runway To Outside Runway | 83 1/4" (6' 11 1/4") | |

| Clearance Under Runways | 70 1/4" (5' 10 1/4") | |

| Clearance Between Columns | 112 5/8" (9' 4 5/8") | |

| Height Of Columns | 89 3/4" (7' 5 3/4") | |

| Maximum Wheel Base | 185" (15' 5") | |

| Drive Thru | 98" (8' 2") | |

| Air Requirement | 85-115 PSI (EXTERNAL AIR SUPPLY REQUIRED) | |

| Motor/Electrical Requirement | 220 volt single (1) phase. A 30 amp breaker is recommended |

|

| Oil Requirement | 3-5 Gallons AW32/AW46 (NOT INCLUDED) | |

| Shipping Weight | 2,900 LBS. | |

| Requires a minimum of 6" of concrete with a 3000 psi. rating | ||

Warranty

"This item is warranted for five (5) years on structural components, two (2) years on hydraulic cylinders, and one (1) year on electric or air/hydraulic power units from the invoice date. Wear items are covered by a 90-day warranty. Our LIMITED warranty policy does not include a labor warranty. ATLAS Automotive Equipment is offered at highly competitive prices, allowing us to provide exceptional value. To maintain these price advantages, ATLAS does not send technicians into the field for equipment repairs. We understand that the buyers of our line of equipment are mechanically inclined or have employees that are mechanically inclined to perform essential repair services and/or maintenance. We also have a list of service technicians who can come to your location at the customer’s expense. NOTE: All warranty claims must be pre-approved by the manufacturer to be valid. The manufacturer shall repair or replace, at their option, for this period, those parts returned to the factory freight prepaid, which prove after inspection to be defective. This warranty will not apply unless the product is installed, used, and maintained in accordance with the manufacturer’s installation, operation, and maintenance instructions. This warranty applies to the original purchaser only and is non-transferable. The warranty covers the products to be free of defects in material and workmanship but does not cover normal maintenance or adjustments, damage, or malfunction caused by improper handling, installation, abuse, misuse, negligence, carelessness of operation, or normal wear and tear. In addition, this warranty does not cover equipment when repairs or alterations have been made or attempted on the manufacturer’s products. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, AND ALL SUCH IMPLIED WARRANTIES ARE EXPRESSLY EXCLUDED. The remedies described are exclusive, and in no event shall the manufacturer, nor any sales agent, distributor or other company affiliated with it or them, be liable for special, consequential, or incidental damages for the breach of or delay in the performance of this warranty. This includes, but is not limited to, loss of profit, rental or substitute equipment, or other commercial loss. The warranty shall be governed under the laws of Canada and shall be subject to the exclusive jurisdiction of the Province or Territory in which the equipment is sold into and shipped to. Prices: Prices and specifications are subject to change without notice. All orders will be invoiced at prices prevailing at the time of shipment. Prices do not include any local, Provincial, or Federal taxes where applicable. All taxes are subject to the rate at where the Atlas products are sold into or shipped to. Returns: Products may not be returned without prior written approval from the manufacturer. Due to the competitiveness of the selling price of these lifts, this warranty policy will be strictly administered and adhered to."Product Videos

Videos Hide Videos Show Videos

Product Reviews

Product Assembly & Setup

Selling automotive equipment we have found that most of our customers are mechanically minded and look forward to settting up and assembling their new purchase. Most items we offer can be setup and assembled by two people within a reasonable time frame. Before tackling this project here are a few tips that we think will make your life a little bit easier:

- Review the manually fully before you begin setup. The manual should be included with your item but if you cannot locate it simply go to the product page on our website and download it for FREE. This manual has been put together and maintained over the years and will include all the tricks we have learned to make the assembly of your as seamless as possible

- Don't like reading or don't need the manual? That's fine, but maybe take a minute and check out the videos we have posted on each of the product pages. We understand that some people have the ability to problem solve on their own but why not get the inside information so you can spend less time having to problem solve?

- If you haven't already received your item, get an uderstanding of you will need to transport or unload

it. Shop equipment like tire changers and wheel balancers are a dream to handle compared to car lifts.

If you are assembling your car lift take time to plan our your install.

- Start by making sure the install location and area(s) surrounding it are clean and clear making it easy for you to move around and manipulate the pieces.

- Try to get the entire crate close to the install area without impeding it. There are some heavy pieces that need to be moved into place and the less you have to move them the better.

- Disassemble the packaging and pieces and have a look through them to ensure all pieces are there and get an idea of what each item is. You are going to need them at one point and if you have someone holding a heavy item while you search out a bolt or hose it is going to be a long day!

- If you are reading the manual, read 2-3 steps ahead of where you are at. We have heard time and time again how a customer has installed their lift to 90% only to find that a hose or cable needed to be put in place two steps earlier and now they have to essentially disassemble the lift only to put a small piece in place and then reassemble it.

- Be sure to review the electrical requirements of the product your are purchasing. Some items are supplied in either 110V or 220V. Others are manufactured so you can just plug it in while some have a "pig tail" which means you will need an electrician to either hard wire it to your panel or install a plug

- If you are assembling a car lift, you will need hydraulic fluid to make the lift work. PLEASE NOTE: we do not supply the hydraulic fluid for your lift. In general we recommend AW-32 hyraulic fluid for use in all of our car lifts (regardless of the type). A 5 gallon pale is typically more than enough and will usually leave you with a little extra

- When filling your hydraulic fluid for the first time don't rush the process. Fill the resevior to 1/3 or 1/2 and then run the lift up and down. Get the air and kinks out and then, when the lift is in the lowest position, fill it to 2/3 or 3/4 and run the lift up and down again. DO NOT fill the resevoir past 1/3 or 1/2 when the lift is in the raised position as there is flud throughout the cyclinders and other components. We have heard many times that a customer has filled the resevoir full when the lift is in the raised position and the as soon as they begin lowering the lift the resevoir becomes overfilled and spills all over the shop. This is a huge mess to clean up.

- Some hydraulic cylinders may be "air locked" from manufacturing which will not allow the piston to extend when pulled by hand. This does not mean the cyclinder is damaged, it is simply a result of the manufacturing process. To overcome this, start by ensuring that your feeder hoses to the cylinder are not connected (this would close the system and will not let air in or out). Using a ratchet strap or similar item, slowly put tension on the piston end and gently apply pressure trying to extend the piston out of the cylinder. Resistance will build up in the first couple inches of extending and then the "air lock" should break. You might get a little pop and the ratchet strap will loosen suddenly (hence the reason to apply pressure slowly) and now you should be able to extend and retract the piston by hand with little effort.

These tips are friendly suggestions from us and the years of experience we have gained working with these products. Although they don't apply to every product, every time we hope that you will take them at face value while still reviewing the other information (such as manuals and videos) we provide in regards to assembling and setting up your product. Your safety and satisfaction are our paramount concerns. If there are any questions or concerns throughout the assembly or operation process of your product please do not hesitate to contact us.

Contact Us

For all customer, vendor and media inquiries we encourage you to contact us VIA your preferred method:

By Phone:

Local 403.398.5020

Toll-Free 866.284.8604

Monday-Friday

8:00am-5:00pm MST

By Fax:

Toll-Free 866.398.5020

By Email:

customercare@atlasautoequipment.ca

In Person

Click here to view our locations.

8:00am - 5:00pm MST

Weekends & Holidays

Closed

NOTICE REGARDING OUR SHOWROOM

In an effort to offer our customers the highest quality products at the most competitive prices our business structure does not allow us to operate a showroom. Removing this expense is one of the many tactics we employ to ensure our customers continue to get the most cutting edge deals.

If you need clarity on specifications, product styles or if you would like more information than what we offer on our site be sure to contact us and one of our friendly customer service staff will be happy to assist you.

Shipping Information

Knowing that each customer will have unique needs when receiving their product, we strive to offer shipping solutions for every customer regardless of their location.

Please contact our friendly customer service staff toll free at 1-866-284-8604 and they will be happy to assist you in finding the most convenient and cost effective options for you to receive your order.

Both shipping and pickup options are available.

Financing

We are happy to be able to offer a financing option as a new method of payment for your purchase.

Available through a Canadian based third party company, financing can be beneficial for many reasons:

- You don't have to pay for the total price upfront

- Depending on information provided there are reasonable or even zero"down payments"

- Amortizing the purchase over a specified period allows you to make budgeted payments

- Having budgeted payments allows you to recover the cost of the machine through revenue over an extended period

- Reasonable interest rates

- Various security options

Whether you just want to make smaller payments or prefer the financing method our third party finance company will work quickly to provide you with all options available.

Their friendly approach ensures that all customers looking to finance or just exploring the possibility will receive accurate information with no hidden fees, terms or tricks.

If you would like more information on financing please contact our Customer Care Team toll free at 866.284.8604 or VIA email customercare@atlasautoequipment.ca.

We also welcome you to contact our leasing partner directly to begin the pre-approval process or to address any of your questions.

Click on the link below and you have access to a payment calculator and the ability to apply for financing online.

ATLAS AUTOMOTIVE EQUIPMENT EXTENDED WARRANTY PROGRAM – CANADA

Terms and Conditions

Atlas Automotive Equipment offers Extended Warranty Programs that reflect our confidence in the quality, reliability, and durability of the following equipment: Atlas ALI Certified Automotive Professional Grade Lifts, Commercial Grade Lifts, Hobbyist Lifts, Alignment Equipment, and Wheel Service Equipment. By purchasing Atlas Automotive Equipment, you are investing not only in top-tier equipment but also in the efficiency and long-term success of your business.

Atlas Automotive Equipment Canada offers two Extended Warranty Programs:

2-Year: BLUE 2+ Warranty

3-Year: PLATINUM 3+ Warranty

Coverage Details

1. Atlas 2 & 4-Post Lifts and Alignment Equipment

Warranty applies to parts only, including hydraulic warranty coverage for hoses, fittings, air/hydraulic pumps(*), and cylinders(*).

2-Year Extended BLUE 2+ Warranty: $395.00 per lift.

3-Year Extended PLATINUM 3+ Warranty: $495.00 per lift.

2. Atlas Wheel Service Equipment

Warranty applies to parts only, including hydraulic warranty coverage for motors(*), computers/power boards(*), transmissions, bead breakers, cylinders(*), and turntable cylinders(*).

2-Year Extended BLUE 2+ Warranty: $395.00 per unit.

3-Year Extended PLATINUM 3+ Warranty: $495.00 per unit.

3. Component Return for Warranty Claims

For warranty claims on components marked with an asterisk (*), customers are required to return the component to an Atlas Automotive Equipment location at their own expense (Calgary, AB; Vaughan, ON; Boucherville, QC) for inspection prior to Warranty credit.

If immediate replacement is required, the customer must purchase the component, and if it is determined that the failure is due to a manufacturer defect (and not lack of maintenance or water in the system), the customer will be credited the cost.

Warranty Limitations

All Factory Warranty and Extended BLUE 2+ and PLATINUM 3+ Warranties cover the replacement of defective parts only. Labor, maintenance, and service calls are not included or implied.

Wearable consumable parts or parts requiring regular maintenance (e.g., pullies, cables,Etc) are excluded from both the Factory Warranty and any Extended Warranty programs.

Eligibility and Conditions

Atlas Automotive Equipment’s Extended BLUE 2+ and PLATINUM 3+ Warranties are valid within Canada and supported by a network of authorized service providers.

These warranties are non-transferable and apply only to the original purchaser. Warranties are void where prohibited by law.

To activate the Extended Warranty, customers must enroll and register the warranty within 30 days of the original equipment purchase. This applies to the equipment and any associated Atlas Equipment Accessories.

Warranties must be registered prior to the installation or use of any equipment.

The warranties apply to Canadian customers only. All prices are listed in Canadian funds, and taxes are extra where applicable.

Enrollment and Contact Information : To enroll in and register for the Extended BLUE 2+ or PLATINUM 3+ Warranty or to learn more about the Standard Manufacturer’s Factory Warranty, visit www.atlasautoequipment.ca or contact our customer support team at 1-866-284-8604.

Final Disclaimer : Wherever you are in Canada, Atlas Automotive Equipment provides expert assistance and prompt service. By choosing the Extended BLUE 2+ or PLATINUM 3+ Warranty, you are not just purchasing a warranty; you are investing in a commitment to quality, reliability, and long-term support.